| Этот текст еще не переведен на русский язык! Этот шаблон должен быть удален после завершения перевода. |

Этот шаблон должен быть удален после завершения перевода.

Head lift is only affected by the elevation difference but not the shape of the Pipeline.

When building a new Pipeline Pump, its Head lift indicators appear as blue markings, which shows the maximum height fluids can go. Additional pumps can be snapped at these markings.

Head lift determines how high fluids can be pushed up. Only the vertical distance, or the difference between the elevation of starting and ending points, matters; it does not depend on the Pipeline's shape. Each meter of head lift can lift the fluid by one meter vertically. Fluids can flow freely along perfectly horizontal pipelines.

Head lift does not depend on the flow rate but can affect it.

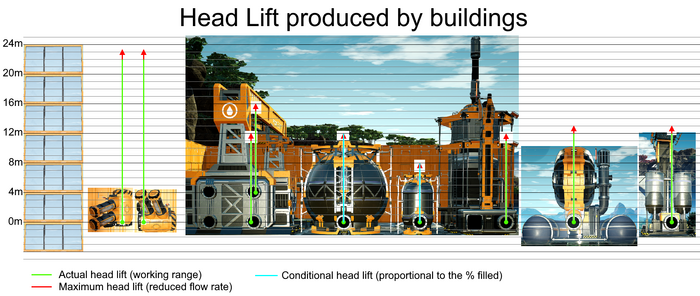

The following buildings can generate head lift:

Pipeline Pump Mk.1 – 20 meters

Pipeline Pump Mk.1 – 20 meters Pipeline Pump Mk.2 – 50 meters

Pipeline Pump Mk.2 – 50 meters Water Extractor,

Water Extractor,  Oil Extractor,

Oil Extractor,  Refinery,

Refinery,  Fluid Freight Platform, ,

Fluid Freight Platform, ,  Packager,

Packager,  Resource Well Extractor,

Resource Well Extractor,  Blender – 10 meters

Blender – 10 meters

The following buildings can store and relay head lift:

Industrial Fluid Buffer – up to 12 meters

Industrial Fluid Buffer – up to 12 meters Fluid Buffer – up to 8 meters

Fluid Buffer – up to 8 meters Pipeline (Mk.1 and Mk.2) and – horizontal: 1.3 meters, vertical: same as pipe length

Pipeline (Mk.1 and Mk.2) and – horizontal: 1.3 meters, vertical: same as pipe length

For example, a Water Extractor outputs Water with a head lift of 10 meters; this means the Water Extractor can push Water up to 10 meters vertically.

Head lift produced by different buildings has a different base starting point, see below.

Head lift and elevation difference[ | ]

The head lift required to fill a fluid container is equal to the elevation difference, measured from the base point of the source of head lift to the top level of the fluid container.

Diagonal pipelines are an exception: the reading of head lift, as displayed on a Pipeline Pump, will be slightly higher and not linear.

Currently, the only way to measure head lift is by constructing a Pipeline Pump on the pipeline at the elevation of measurement then interact E with it. Head lift can be estimated by calculating the elevation difference, using Walls (four meters high) or Foundations (four meters, two meters, or one meter high).

Recommended, actual and maximum head lift[ | ]

The recommended head lift can be found in the building's description in the build menu. Within the recommended head lift, fluids flow freely without resistance. The system may continue to work one or two meters higher than that, which marks the actual head lift. Beyond that, flow rate drops abruptly, down to zero flow around two to three meters beyond the recommended head lift, which marks the 'maximum head lift'. When approaching the maximum head lift, fluids start to act in strange ways: fluid may or may not flow, and may sometimes oscillate forward and backward while attempting to achieve the head lift equilibrium, producing inconsistent behavior. Thus, it is always recommended to keep the system within the actual head lift.

Note: See Pipelines and Fluid Buffers below for how buffers interact with head lift.

Pipelines and Fluid Buffers[ | ]

A perfect horizontal Pipeline requires 1.3 meters of head lift to be filled regardless of its length. As it fills up, it also stores its own head lift proportionally, up to 1.3 meters. This effect will then propagate to the next pipeline and cause the successive pipelines to be filled up. A not completely filled pipe segment has a head lift of 1.3 meters. Fully saturated pipes can propagate more than that (be it from a pump or other buildings). Fluids take time to fill up a very long pipe, but once it is fully filled, fluids in it can flow with the maximum flow rate (or whatever the source's flow rate is).

A vertical pipeline can store maximum head lift equal to its vertical length, measured from its bottom end to the top end. Its stored head lift is proportional to the percentage of the fluid in it; for instance, a half-filled 10-meter pipeline stores five meters of head lift. A vertical pipeline needs to be fully filled before the next pipeline above it can start to receive fluid. A very tall pipe requires a very high head lift to be filled. If a lower head lift is provided, it can only be filled partially.

If somehow the fluid source is stopped and the source's head lift drops, the previously stored head lift in pipes will attempt to equalize among connected pipelines; this means fluids can backflow from the pipes with higher head lift to the pipes with lower head lift, as pipelines are bi-directional in nature. For example, if there are two horizontal pipelines with identical length connected in series, with one of them filled and the other one emptied, then the fluid within them will equalize themselves until both are filled equally, that is, 50% full. During this equalization process, the fluid flow can oscillate back and forth, taking a long time before it fully stabilizes.

All of the above principles also hold for Fluid Buffers and Industrial Fluid Buffers – they are just Pipelines but with much larger capacity and head lift. Note that their stored head lift is counted from the pipe inlet level, not from the Foundation level. Combining all the above knowledge, chaining multiple Fluid Buffers in series is a bad idea as the system requires a very long start-up time – consider attaching buffers to the 'sideways' of a Pipeline instead, by using Junctions.

Head lift merging and splitting[ | ]

Pipeline Pump behavior and usage

When a single fluid source is split into multiple pipelines via a Pipeline Junction Cross, the output head lift of each pipe is equal to the input: outA = outB = in. The flow rate is split, but the head lift is not.

When multiple fluid sources with different head lifts are joined via a Pipeline Junction Cross, the highest head lift among them is applied to the entire pipe network: out = Max (inA, inB). This 'sharing' effect will not hinder the output of fluid buildings with a lower head lift or positioned at the lower points; for instance, a Water Extractor with its output pipe under a head lift of much greater than 12 meters will still be able to push out Water, provided there is space allowed for it to do so.

Both of the above hold true regardless of the flow rate of input and output pipelines.

Pipeline Pumps[ | ]

A non-powered Pipeline Pump acts as a one-way valve and resets the head lift back to zero meters. A powered Pipeline Pump resets the head lift to 22 or 52 meters (depending on Mk. level) as long as there is fluid reaching its input, regardless of the head lift preceding it. That also means building multiple Pipeline Pumps nearby is very inefficient, and each of them costs power to function. Pipeline Pumps should be spaced out 20 meters vertically, measured center-to-center.

Exploits[ | ]

Pipeline Pumps, if used in large quantities, can be a burden to the power grid, thus an innovative solution is highly desirable to minimize power usage. When multiple fluid sources with different head lifts are connected to a single or multiple pipelines, the highest head lift among them will be applied to the entire connected pipe network. This head lift sharing effect makes head lift exploits possible. By using a water tower with zero output, free-energy lifting can be achieved. (credits go to McGalleon)

- To do so, first construct as many Water Extractors at the lower area as you need.

- Build a floating factory above the lower Extractors at any height you wish. Connect the pipes between the factory needing the Water and those Extractors. In the image below, an Industrial Fluid Buffer is used, you can replace it with the actual factory setup.

- Around the same height, construct a Fluid Buffer and fill it up, either by using another Water Extractor or using Pipeline Pumps from below. Let's call this Buffer 'water tower'.

- From the water tower, construct a downward pipe and connect it to the lower pipeline via junctions. If you have a large setup consisting of multiple parallel pipelines, connect all of them at the lower point.

- Construct a Valve on the water tower downward pipe to restrict its flow to zero м3/мин. The Valve can be located at any position between the water tower and the lower junction, however, if it is above the head lift height of the Water Extractors, the pipe segment between the valve and the junction can become less than 100% full, in which case it will stop transmitting head lift from beyond the valve (this will only happen if the output side also becomes lower than the valve height, otherwise the output will cause enough head lift to refill the pipe). Therefore it's best to put the valve close to the extractors to avoid surprise jams.

- Once the downward-facing pipe and the water tower are full, you may deconstruct the pipes, Extractor, and Pipeline Pumps (if any) that are used to fill up the buffer. Since the water tower will always be full, no energy is required to maintain the head lift for the water tower.

- All the pipes will then share the head lift from the water tower. Enjoy the free-energy fluid lifts!

Fluid Freight Platform[ | ]

A Fluid Freight Platform does not generate opposing head lift when being filled up, and thus a fluid source can easily fill it up as long as the pipe inlet level of the Fluid Platform is within the source's head lift. As such it is advised to always use its lower pipe inlet first, followed by the upper inlet if the input rate higher than the max flow rate of used pipes is desired.

A Fluid Freight Platform requires a connected powered Train Station to receive and/or output fluid. It can output fluid regardless if it is set to load or unload.

The actual head lift provided by a Fluid Freight Platform is 11 meters, measured from the pipe connector. As such, it is always advantageous to use the upper pipe outlet first, followed by the lower outlet if the output rate higher than the max flow rate of used pipes is desired.

Gallery[ | ]

| |||||||||||||||||||||||||||||

ru:Подъём напора